So, you want to make candy that you can feel good about, and that your customers can feel good about buying? I've been on this journey for a while, and it's a lot. It's about thinking through everything—the ingredients, the power you use, how you make things, even the box it comes in. It's not just about making yourself look good; it's about actually doing good. And honestly, I've found that people really do care. It makes a difference.

Here are the big things I try to keep in mind:

-

Ethical Ingredient Sourcing: Knowing where your stuff comes from. I mean, really knowing. Are the ingredients organic? Are the people who grow them treated right?

-

Renewable Energy: This one felt huge at first, but it's about looking at how much power you're using and finding smarter ways to do things, like using solar.

-

Cleaner Production: Thinking about things like water. You'd be surprised how much you use. It's about being less wasteful.

-

Eco-Friendly Packaging: I hate getting a tiny product in a giant box full of plastic. There are so many better options now.

-

Transparency and Quality Control: This is just about being honest. Saying what you do, doing what you say, and making sure every single piece of candy is something you're proud of.

Why It Matters:

- Consumer Demand: 66% of buyers are willing to pay more for eco-conscious products.

- Cost Savings: Recycling and resource efficiency can save thousands annually.

- Market Edge: Brands like MommaBear Organics thrive by integrating these practices.

Let’s dive into the details of how you can start making a difference - both for the planet and your business.

Making 'Climate Candy' From Upcycled Fruits and Veggies | Women Entrepreneurs

Ethical Ingredient Sourcing

This is where it all begins, right? The actual stuff that goes into the candy. I used to think as long as it was a good ingredient, that was enough. But it's so much more than that. It's about making sure the whole process, from the farm to your kitchen, is something you can stand behind.

Choose Organic and Non-GMO Ingredients

Look, going organic feels complicated at first. There are all these rules. I learned that for something to have that official USDA organic label, the land can't have had certain stuff on it for years. And you have to document everything. I mean everything. You get audited and everything. But it’s worth it. It’s a promise, you know? A promise to your customers that what’s inside is clean and made with care. It’s not just a sticker; it's about being transparent.

Work with Fair Trade and Ethical Suppliers

This one really gets to me. It's not just about the planet; it's about the people. I started looking into where my ingredients were coming from and realized I had no idea how the farmers were being treated. So now, I try to work with suppliers who have fair trade certifications. It means they're making sure workers get fair wages and have safe places to work, and that no kids are being forced to work. It takes more effort to check on this stuff, yeah, but how could you not? You have to be able to sleep at night.

Source Locally Whenever Possible

And then it hit me... why am I ordering ingredients from halfway across the world when there are amazing farmers right here? Sourcing locally just makes so much sense. You cut down on all that pollution from shipping, you're supporting your own community, and honestly, the ingredients are often fresher. I’ve started going to local farmers' markets and just talking to people. Building those relationships has been one of the best parts of this whole thing. You change your production schedule a bit to match what's in season, but it's a small price to pay for doing things right.

Okay, so once you feel good about your ingredients, the next big thing is how you actually make the candy.

Renewable Energy in Production

Expanding on the idea of ethical sourcing, integrating renewable energy into production processes takes sustainability to the next level. By switching to renewable energy, companies can significantly reduce their environmental impact. With manufacturing responsible for 76% of the industrial sector's energy use in the U.S. and the average factory consuming 9,000 MWh of energy annually, the opportunity for meaningful change is immense.

Adopt Renewable Energy Sources

Switching to solar or wind power felt like this huge, impossible step at first. But it's becoming more and more doable. I read that the U.S. is trying to get most of its energy from renewable sources by 2030, which is pretty cool. For some people, wind power is a great option. For others, like us, solar just makes more sense. I saw this story about a furniture maker who put solar panels on their roof and it now powers most of their factory. How amazing is that? There are even government programs now that help you afford it. It’s a big investment, but it feels like the right thing to do.

Improve Energy Efficiency

But it's not just about giant solar panels, you know? A lot of it is just being smarter about the little things. We did an energy audit, which basically just showed us all the places we were wasting power. It was eye-opening. Simple things, like switching to LED lights or getting systems that turn things off automatically, can cut your energy use by a ton. It's the small habits that really add up over time, and they save you money, too.

Track and Share Energy Initiatives

I think it’s important to be open about this stuff. We're trying our best, but we're not perfect. So we track our energy use and we share it. It keeps us accountable. And I think people appreciate the honesty. When you're open about what you're trying to do, people trust you more. It's not about pretending to be perfect; it's about showing you're trying.

Next up, something I never thought much about before: water.

Clean Production Methods

You really start to see how everything is connected. It’s not just ingredients and energy; it’s about every single part of the process, right down to the water you use for cleaning up.

Use Water-Efficient Systems

I was shocked when I realized how much water we were using. It’s one of those invisible things you don’t even think about. We found these systems that can capture the steam from when we're cooking and turn it back into water we can use for cleaning. It's so clever. Little things, too, like using better nozzles on our hoses and having things shut off automatically. It all makes a difference. I saw that Lindt, the chocolate company, put in a system to recover heat from their wastewater. It's just about looking at every step and asking, "Can we be smarter about this?"

Eco-Friendly Packaging Solutions

You know that feeling when you order something small and it arrives in a massive box filled with plastic pillows? I hate that. The packaging is the first thing your customer sees, and for me, it’s a huge signal about what a company cares about. I read that 90% of people are more likely to buy from brands that are trying to be sustainable with their packaging. It just makes sense.

Choose Recyclable or Compostable Materials

This has been a fun one to research. There are so many cool materials out there now. Instead of plastic, you can use compostable cellophane made from plants. It looks and feels like the normal stuff, but it breaks down naturally. You just have to be careful to get the right kind, without plastic coatings that mess up the composting process. I found a company that makes bags from wood pulp that break down in a few months. It's amazing what's possible.

Design Minimal Packaging

This one feels like a no-brainer. Just... use less stuff. Right? We try to make our boxes fit our products just right, so we don't need all that extra filler. It saves material, it costs less to ship, and it’s just better for the planet. It’s not about fancy, complicated packaging; it’s about being thoughtful and efficient.

Label Packaging Features Clearly

I think it's our job to make it easy for people. No one wants to stand in their kitchen trying to figure out if something is recyclable or not. We try to use really clear labels, like "Compost this!" or "This box is made from recycled paper." No vague "eco-friendly" stuff that doesn't mean anything. Just be straight with people. It builds trust and actually helps them do the right thing.

Quality Control and Transparency

At the end of the day, this is all about trust. People want to know that what they're eating is safe, high-quality, and made by people who are being honest with them. Especially when you're making something for wellness, for families... you just can't cut corners.

Maintain Rigorous Quality Control

For me, every batch has to be right. It's a non-negotiable. We have standardized recipes and we test everything. When you're using natural ingredients, there's always a little variation, so you have to be extra careful. We track everything, from the ingredient source to the final lollipop. It's a lot of work, but it means we can stand behind every single thing we sell. It’s about being proud of what you make.

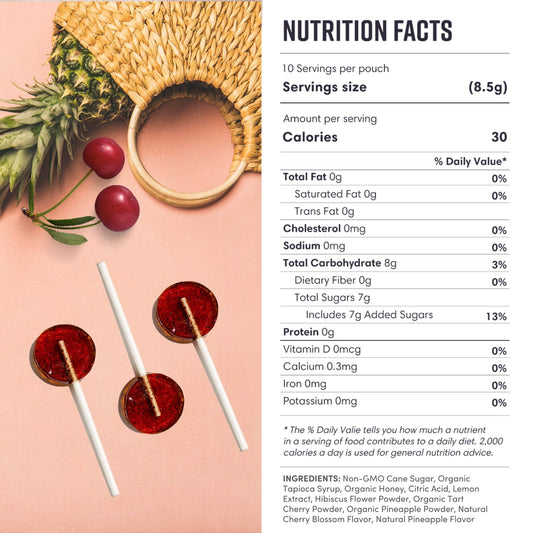

Provide Clear Product Labeling

I get so frustrated at the store when I see a label with a million ingredients I can't pronounce. Why does it have to be so complicated? We try to keep our labels simple. List the ingredients in plain English. I read about RXBAR and how they just put their main ingredients right on the front of the package, and their sales exploded. People are hungry for honesty. If you can, add a QR code so people who want to know more can find it easily. Just tell the truth.

Commit to Continuous Improvement

Look, we're not perfect. No one is. This whole thing is a journey, and we're learning as we go. The goal is just to be a little bit better tomorrow than we were today. We listen to feedback from our customers, we keep an eye out for new, better materials, and we set goals for ourselves. I saw that Mars is spending millions to make their dairy supply chain better. That's huge. For us, it’s smaller steps, but it's the same idea. Just keep moving in the right direction.

Example: MommaBear Organics' Commitment to Environmental Responsibility

Okay, so this is our story. This is what we try to do every day.

MommaBear Organics is a company led by women, and we make organic lollipops that are meant to help with little everyday problems. All our stuff is organic, non-GMO, gluten-free, dairy-free... none of the junk. We make them by hand in small batches with ingredients we've really thought about.

Thoughtful Ingredient Sourcing

This is the heart of it for us. We only work with suppliers who use regenerative agriculture—that’s a way of farming that actually makes the soil healthier. We want our ingredients to not just be organic, but to come from farms that are helping to heal the earth.

Small-Batch Production for Sustainability

We make our lollipops in small batches. It's a choice. It means we don't have a ton of waste from overproducing, and we save resources. It just feels more responsible than running a massive factory 24/7. It keeps us close to the process.

Eco-Friendly Packaging

We're always thinking about packaging. We use materials that can be recycled or that will biodegrade. We want the whole experience of our lollipops, from the moment you open the box to the moment you're done with the stick, to be as gentle on the planet as possible.

Positive Customer Feedback and Industry Recognition

We’ve been really lucky. We received an endorsement from Parent Tested Parent Approved (PTPA), and our customers on Amazon seem to really get what we're doing. People write to us and say they appreciate the organic ingredients and our effort to be responsible. That means the world to us. It shows that all these little choices really do matter. We're just trying to prove that you can be a small business and still make a big, positive impact.

Conclusion

Trying to do all of this... it’s a lot. Some days it feels overwhelming, like we'll never get it all right. But then I remember it's not about being perfect. It's about taking it one step at a time, making one better choice, and then another. It’s about caring enough to try. I read somewhere that food production is going to have to increase by a huge amount, like 70%, in the next few decades. That's a heavy thought. The companies that are going to be around for the long haul will be the ones that figured this stuff out. It’s not just about business, though. It’s about the kind of world we're leaving behind. And that feels worth the effort.

FAQs

What are some affordable ways for small candy makers to adopt sustainable production practices?

I get this question a lot. It can feel like you need a huge budget, but you really don't. You can start small. Things like switching to LED lightbulbs or getting more energy-efficient appliances can save you money on your bills in the long run. When it comes to packaging, just look for simple recyclable or biodegradable options—sometimes they’re not much more expensive, and your customers will love it.

And honestly, sourcing locally can sometimes save you money on shipping. Plus, making things in smaller batches means you waste less. It’s about being clever and intentional, not just throwing money at the problem.

How can candy manufacturers ensure transparency in sustainable production, and why does it matter?

For me, transparency is just about being honest. You can use systems that track your ingredients all the way back to the farm they came from. Then, just share that information! Put it on your website. Talk about it on social media. People want to know the story behind their food.

It matters because there are real problems out there, like deforestation and unfair labor, and being transparent is how we hold ourselves and our suppliers accountable. When you're open about what you're doing, you build a ton of trust with your customers. They feel like they're part of the journey with you.

How does using renewable energy improve the sustainability of candy production?

Switching to something like solar or wind power is a game-changer for your carbon footprint. It drastically cuts down on the pollution your facility creates. But beyond that, it can actually make your business more stable. You're not as dependent on the fluctuating costs of regular energy.

Honestly, it just feels like the right direction to move in. It's a way of showing you're serious about the future, not just for your company, but for everyone. It’s one of the biggest ways we can contribute to a healthier planet.

Related posts

- Ultimate Guide to Ethical Ingredient Sourcing

- Ultimate Guide to Ethical Supply Chains in Organic Candy

- Seed-Bearing Lollipop Sticks: A Green Solution

- Best Organic Candies for Relaxation in 2025